In modern industry, caring for the environment and sustainability have shifted from choices to necessary duties. This green change is mainly about managing water – it’s as valuable as it is scarce. Sludge dewatering systems are vital in dealing with this issue. They’re beneficial technology for making industries more sustainable, particularly when reusing water.

What are Sludge Dewatering Systems?

These represent a collection of technologies that divide liquid from solids in the sludge, which is wastewater treatment’s byproduct. This procedure notably lessens sludge volume, making its removal more cost-effective and better for the environment. More crucially, this process enables the recovery and reuse of water from within the sludge, which plays an integral part in managing the sustainable use of water within industries.

The Industrial Imperative for Water Reuse

The industrial sector is among the largest water consumers globally. It uses vast quantities for processes ranging from cooling and cleaning to product incorporation. Considering the rising shortage of freshwater resources and growing regulatory and societal demands, businesses need to reduce water use and wastage. This necessity is where sludge dewatering systems become essential.

By making the removal and treatment of water from sludge efficient, these systems guarantee that water can be recycled and reused safely and effectively within industrial operations. This process conserves precious water resources and significantly reduces the environmental footprint of industrial activity.

How Sludge Dewatering Systems Work

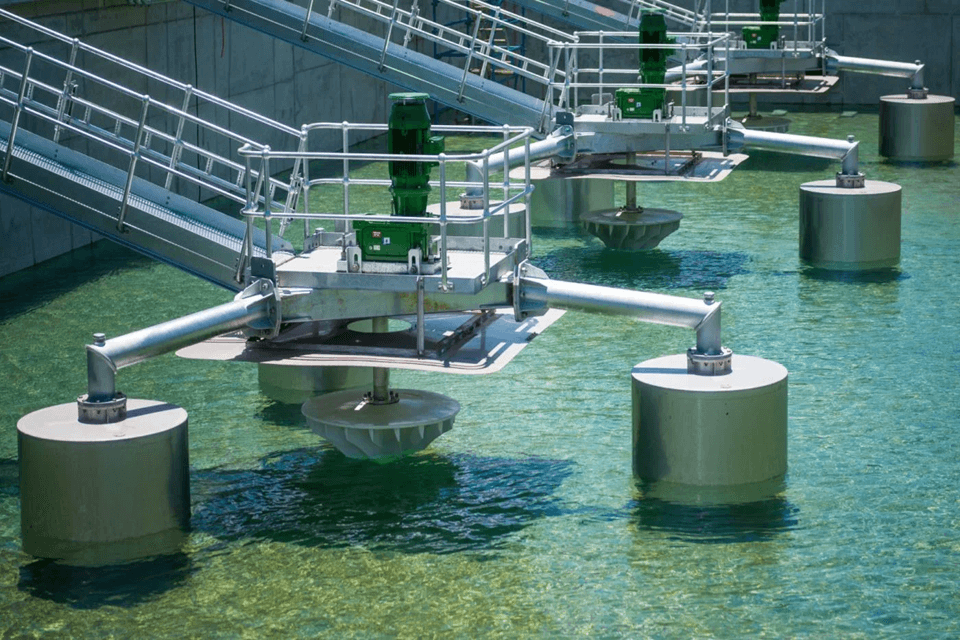

The process of dewatering sludge is composed of multiple stages. Usually, it begins with the chemical handling of sludge to make the division between solids and liquids easy. After this phase, many systems use mechanical methods such as centrifugation or belt press filtration or screw pressing to physically separate water from solid in the sludge.

The choice of technology depends on various factors. They consider factors such as the type of sludge, how much treatment is needed and specific water quality requisites for reuse. Advancements in dewatering technology keep improving their functionality and productivity, giving industries a variety of solutions adapted to their unique demands.

The Environmental and Economic Benefits of Sludge Dewatering

The positive effects on the environment from using sludge dewatering systems in industry are enormous. For one, it helps water to be used again, significantly decreasing the need to take new water from nature. This way, we can save natural places and many different types of life forms. Moreover, these methods make waste smaller before going into landfills or being released into bodies of water, lowering pollution and harm to aquatic animals.

From an economic perspective, the advantages are equally compelling. Reducing water usage translates into decreased water procurement costs. Moreover, by minimising the volume of sludge for disposal, industries can achieve substantial savings in waste management expenses. Furthermore, in several areas, businesses can take advantage of government support to embrace technologies that save water. This advantage makes the financial practicality of sludge dewatering systems even more attractive.

Overcoming Challenges and Looking Ahead

Even though they have obvious advantages, the initial investment you need to put in can be a lot, and running these operations needs constant upkeep and people with suitable skills. Also, the rules about reusing water are complex and change often depending on the area, so proper planning for regulations is essential.

Yet, the long-term environmental and economic profits are much bigger than these early obstacles. As companies keep changing towards more sustainable methods, the place of sludge dewatering systems in their ecological plan becomes more important.

Conclusion

In the journey towards industrial sustainability, efficiently managing water is essential. Sludge dewatering systems are key technical partners in this regard, allowing industries to lessen their environmental footprint while improving economic benefits.